What We Do

Revolutionizing Grain Storage with Innovation

Four Options. Tons of Benefits.

Research-Scale Sensing

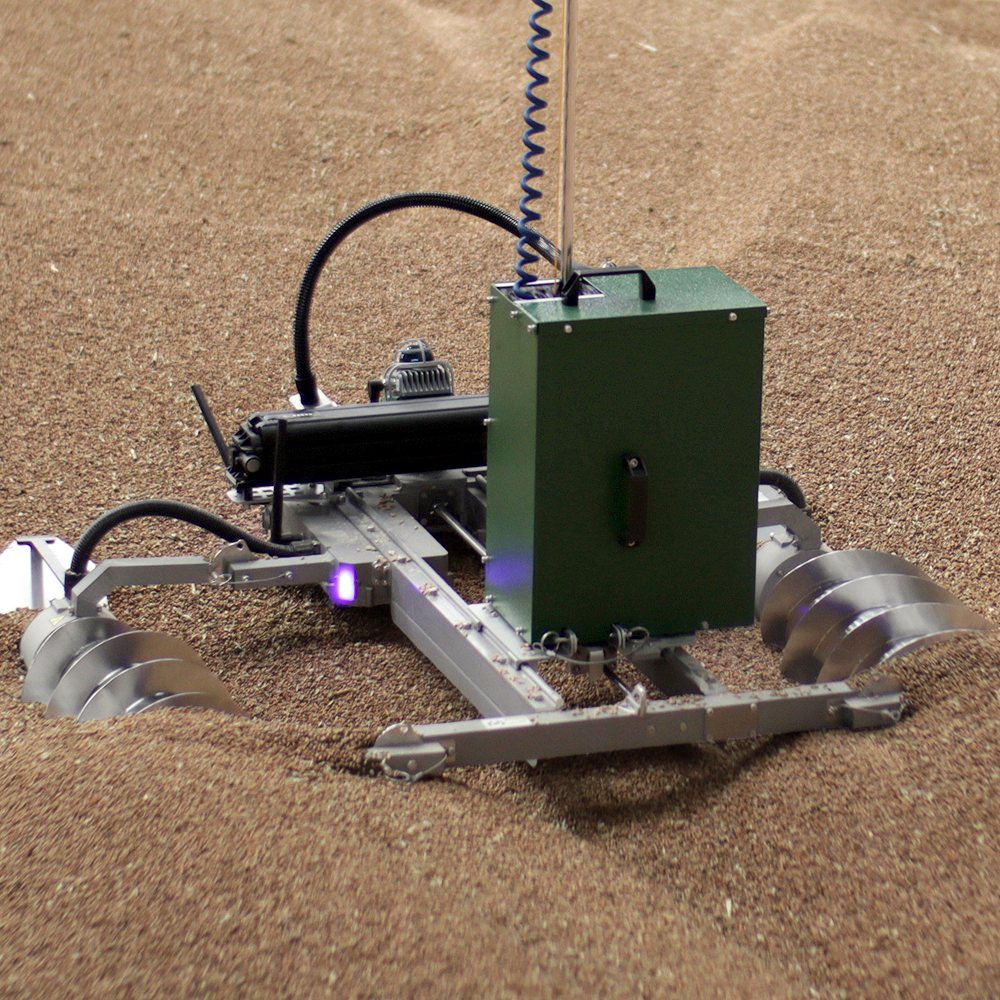

CROVERMini

Research Sensing

Sampling Area

Lab-scale Experiments

Great For

Researchers, labs, non-grain and bulk solid use

Small-scale Sensing

Temperature

Humidity

Sampling Configuration

❌

Sensing-Only

CROVERBasic

Sensing Configuration

Sampling Area

Medium to Large Scale

Great For

Farmers, Agri Coops, all-size operators and transports

Sensing Configuration

Temperature

Moisture

CO2

Precise Depth

Data Visualization

Sampling Configuration

❌

Most Popular!

Full System

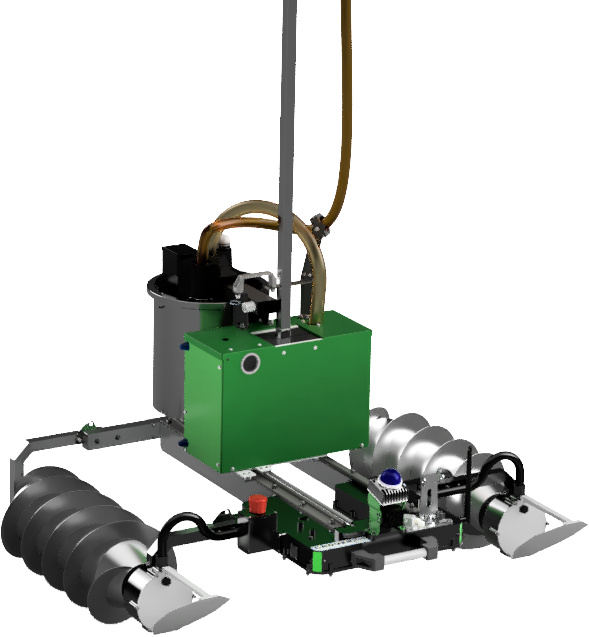

CROVERPro

Sampling + Sensing

Sampling Area

Medium to Large Scale

Great For

Farmers, Agri Coops, all-size operators and transports

Sensing Configuration

Temperature

Moisture

CO2

Precise Depth

Data Visualization

Sampling Configuration

Sample Size: up to 9L

Payload Carry: up to 110 LB

Collect: grain, pellets, powders and more!

Coming Soon!

Autonomous

AutoCROVER

Projected Higher Cost

Buy the full system

today. Get the Autonomous Update for FREE when available!

(special promotion for orders placed in 2025)

Fully Autonomous Sampling and Sensing System!

The Crover Grain Storage Management System

A portable robotic solution designed to monitor and protect grain stored in warehouses and silos. With precise readings of temperature, moisture, and CO₂ levels, CROVER enables you to:

01

Prevent spoilage before it happens.

02

Save time with remote monitoring.

03

Ensure compliance with health and safety regulations.

04

Ensure compliance with health and safety regulations.

Millions of tons of grain are lost annually to spoilage, moisture, and poor storage conditions!

For farmers and grain operators, this means wasted resources, lost profits, and regulatory challenges. Traditional monitoring methods often fall short, providing limited or outdated data and requiring risky manual inspections.

Crover to the Rescue!

CROVER provides a portable robotic grain monitoring system that simplifies and improves storage management. Using our patented “grain-swimming” technology, CROVER enables operators to collect high-resolution data on the condition of their grain bulks, ensuring proactive and efficient management.

Real results. For you.

REPORTS AND NOTIFICATIONS

- Identify hotspots and wetspots early

- Help prevent infestations

- Reduce mass and quality losses

- Reduce energy consumption from cooling and aeration

- Enables accurate IPM

ACCURATE SENSOR READINGS

- Measured at depth within the bulk

- Temperature

- Moisture

- CO2

…more coming soon

STIRRING THE GRAIN

- Break and prevent crusts

- Help keep the grain aerated

- Help break and prevent bridging and ratholing

REPRESENTATIVE GRAIN SAMPLES

- Collected at depth

- Can be used for traceability and for laboratory analysis

Crover will make significant contributions to the agricultural industry and help safeguard post-harvest the hard work that farmers put in to produce their grain.

I see this product, the CROVER robot [...] as a game-changer for the industry. [...] And that’s what the younger generations are looking for, to be able to be storekeepers and look after grain effectively.

Trust us, it's very special!

Proprietary technology. Transforming grain storage. Making life easier!

01 Revolutionary Technology

Our robots are powered by the world’s first proprietary technology for locomotion in granular materials. This enables omni-directional movement on and beneath the surface of grains, sand, and powders, unlocking previously inaccessible data.

02 Practical Benefits

Prevent Spoilage: Identify and address moisture, temperature, and CO₂ issues before they escalate.

Improve Safety: Eliminate the need to walk on grain, drastically reducing the risk of engulfment.

Save Time & Labor: Collect data remotely, reducing manual inspections.

03 Advanced Features

- Real-time condition monitoring through an intuitive web app.

- Grain aeration to prevent crust formation.

- Representative sampling for traceability and laboratory analysis.

The Tech behind Crover

Our patented technology is based on a groundbreaking discovery in granular physics: the coupling between rotational and translational motion in granular media. This allows our robots to “swim” through bulk solids like grains, powders, and sand — Think of it as plane wings, but for the underground of granular environments.